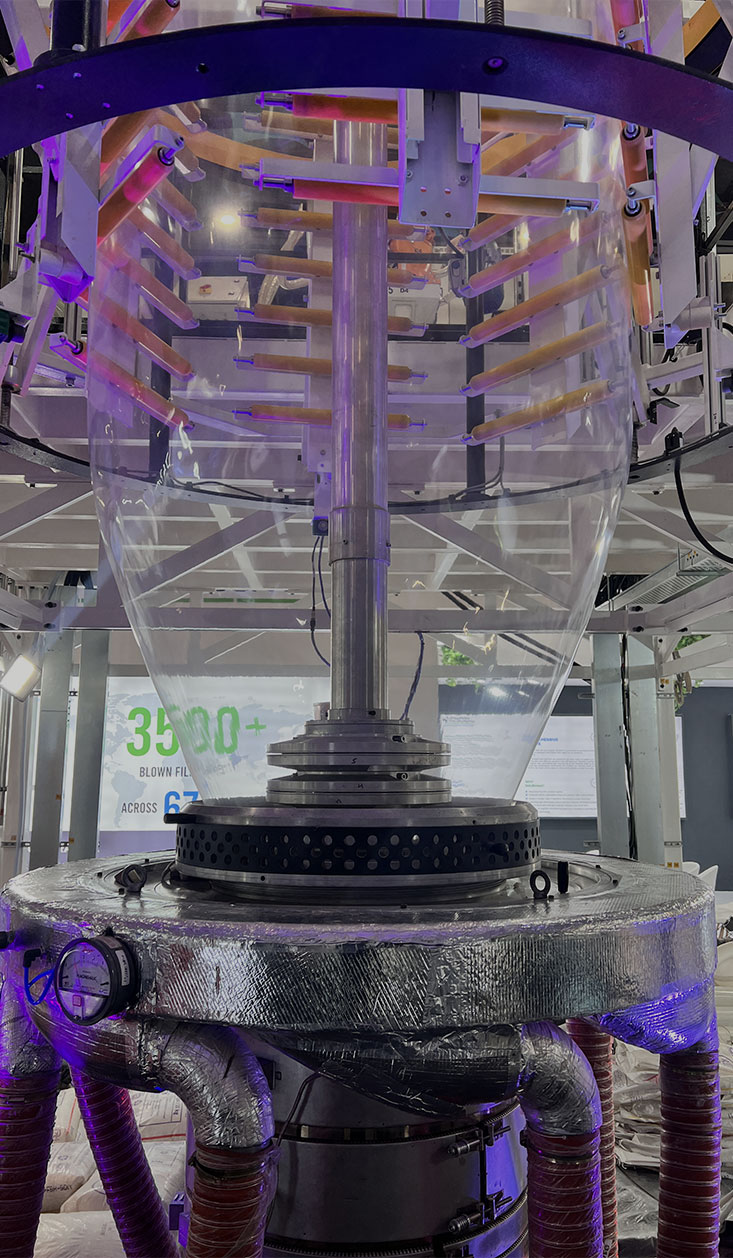

Boost your film production efficiency with Shubham Extrusion's 3-Layer Shrink Film Plant, a next-generation blown film extrusion system designed for quality, strength, and sustainability. Our technology enables high-speed production of durable, multi-layered plastic films tailored for industrial, consumer, and agricultural applications.

Uncompromising Quality: Precision-engineered components deliver optimal performance and reliability.

Tailor-Made Configuration: Fully customizable to suit your specific application and production requirements.

Explore the Product Explore the ProductEnhanced puncture resistance and load-holding performance.

Reduce raw material expenses with recycled middle-layer compatibility.

Tailor film structure to application demands using advanced co-extrusion.

Delivers 180–330 kg/hr with consistent film quality.

Advanced heating systems and optimized cooling reduce power usage.

Supports biodegradable and eco-friendly resin usage.

Compatible with LL, LDPE, HDPE, HMHDPE, EVA, and metallocene.

Our 3-layer films are used globally across industries:

General Purpose Film

Surface Protection Film

Tarpaulin Film

Lamination Film

Shrink Hood Film

FIBC Liners / Mattress Covers

Food Packaging Film

LD-Shrink Film

Milk Packaging Film

Stretch Film

Courier Bags

Water Packaging Film

Atta (Flour) Packaging Film

Mulch films

Agroshed net films

| Parameter | Specification |

|---|---|

| Polymer Compatibility | LL / LDPE / HM / HDPE / EVA / metallocene |

| Thickness Range | 20 – 200 microns |

| Layflat Range | 1200 – 2100 mm |

| Output Capacity | 180 – 330 kg/hr |

With over 27 years of experience and thousands of successful installations, Shubham Extrusion is trusted for innovation, precision engineering, and after-sales excellence. Our 3-Layer Shrink Film Plant is crafted for long-term performance, offering customers measurable ROI, reduced waste, and superior product output.